Factory supplier 500W s&a fiber laser chiller water cooled for laser marking machine chiller

Product Description

Factory supplier 500W s&a fiber Laser Chiller water cooled for Laser Marking Machine chiller

Product Description

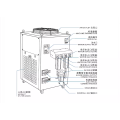

Main features of Fiber Laser Chiller (1) Main parts: Adopt new imported well-known brand compressors, which are safe and environmentally friendly, energy-saving and durable. (2) Spare parts: Most of the original products of "Special Domain S&A" are adopted, with various arrangements and configurations, stable working performance, and long. (3) Function: 1. Optional environmentally friendly refrigerant; 2. The temperature control accuracy can reach ±0.3℃; 3. The intelligent thermostat of the laser chiller has two temperature control modes, which are suitable for different use occasions; it has a variety of settings and fault display functions; 4. The dual-temperature dual-control mode meets the different cooling needs of the fiber laser body and lens; 5. Adopt ion adsorption filtration and detection, which meets the requirements of fiber laser; 6. With multiple alarm protection functions: compressor delay protection; compressor over-current protection; water flow alarm; temperature over-high/low alarm; 7. Multi-national power specifications, CE, RoHS REACH certification; 8. Longevity and durability, operation rehabilitation; 9. Optional heater and purified water configuration.

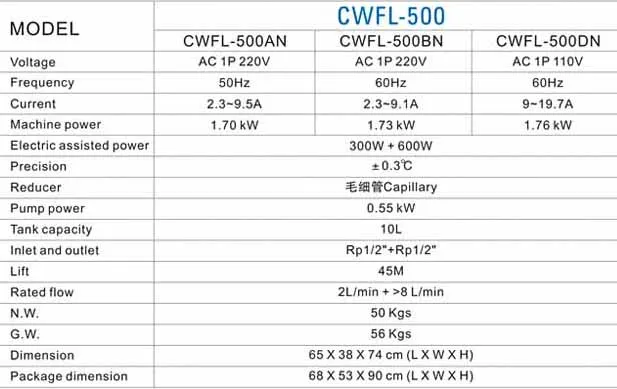

Parameter for Fiber Laser Chiller CWFL-500W

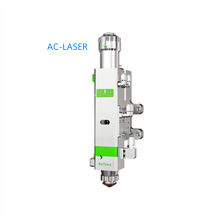

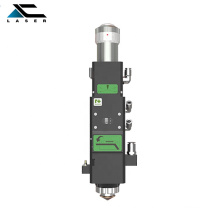

Fiber Laser Chiller

1.The outer sheet metal of the S&A Fiber Laser Chiller, both devices are independently produced, and the high-power IPG fiber laser is used for welding, cutting and drilling to avoid water leakage. 2.High-precision temperature Control System, dual temperature control cycle refrigeration function, two independent temperature control systems simultaneously cool the fiber optic main body and QBH connector 3.Multiple alarm functions to protect the laser in all directions. When receiving an alarm signal from the chiller, to protect the laser, please shut down for maintenance.

Fiber Laser Chiller

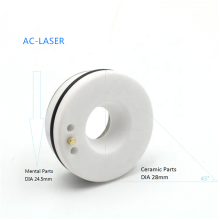

Supporting water pressure gauge: It is convenient to observe the water pressure of the pump. Installation of drain valve: convenient for draining.

Supporting double inlet and double outlet circulating water interface and water level gauge.

The water inlet of the water chiller is connected to the water outlet of the Laser Machine, and the water outlet of the water chiller is connected to the water inlet of the laser machine.

Fan of Fiber Laser Chiller

Use branded fans to reduce the failure rate of parts and ensure quality.

Fiber Laser Chiller application

S&A Fiber Laser Chiller production workshop

Strictly implement the ISO production management system, adopt batch modular standard production, and standard parts reach 80%. This is the root of stable quality.

S&A Fiber Laser Chillerl aboratory test system

Have a complete laboratory test system to simulate the actual operating environment of the chiller, and quality assurance.

Technical Parameters

Company Profie

Exhibition & Visiting

Packing & Shiping

After-sales Service

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers are available to serve machinery overseas. Only $200.00 service fee is charged per day.

* 24 hours hotline .Online installation and operation instruction.

* Life long machines Consultant

*More than 10 people of R&D team from optical,mechanical,electrical and software are in charged of designing, installation,

production, test and after-sale service.

* Engineers are available to serve machinery overseas. Only $200.00 service fee is charged per day.

* 24 hours hotline .Online installation and operation instruction.

* Life long machines Consultant

*More than 10 people of R&D team from optical,mechanical,electrical and software are in charged of designing, installation,

production, test and after-sale service.

FAQ

Q: How to Install the machine?

A: After receive our machine, customers do not need to install it and can use it directly.

Q: How to operate the machine? is training necessary?

A: The machine is mainly controlled by software. It’s very easy, not complicated. Before shipment, we will make a simple operation manual with pictures and provide user manual of software. Generally speaking, an operator, who is not familiar with fiber laser marking machine before can still operate it very well. According to customers’ requests, we can send our technician to customer’ plant for machine training or customers can come to our plant for machine training if needed.

Q: In case machine exists problem, how to do after sales service?

A: We provide two years machine warranty. During the 1 year warranty, in case machine exists problem, we will provide parts required with free of charge by express. But as for the parts damaged by artificially, it does not fall within our warranty list. After the warranty, we still provide lifetime service.

Q: What’s delivery time?

Q: What’s delivery time?

A: Generally speaking, lead time is 5-7 working days after receive the payment.

Q: Can we add a protection cover?

A: Yes, we can add a protection cover if you need. We can customize the design as customers’ requests.

Product Categories : Fiber Laser Cutting & Welding Parts > Laser Chiller

Other Products

Hot Products

Hot Sale High Speed Galvo HeadJS2208 CO2 For Laser Engraving MachineHigh Precision marking Laser Galvo Scanner JS2808 For Jewelleryco2 laser control board for markingco2 galvo 3d headLaser marking machine high reliable laser scanner galvo laser diode module with long life spanLaser cleaning galvo scanner deeply clean metal surface rust and corrosionHigh speed and prescion auto focus galvo scanner for laser marking machine and engraving machineBeauty salon medical center portable multifractional RF CO2 fractional skin whitening machinehigh effective CO2 galvo mirror Sillion basic glass basic laser marking machine laser engraving machine1064nm yag f-theta scan lens use for laser marking machine20w 30w bearing fiber laser marking machine metal laser marking machineaperture 12mm yag laser scanner aperture 16mm digital co2 scanner best selling yag laser scanner for laser marking systemgood promotion fiber 1064nm galvo scanner galvo scanner mirror galvo scanner and controller7 joint articulated arm for laser RF CO2 fractional armlarge format dynamic focus laser galvo scanner CO2 10600nm laser20w Fiber Laser Max Fiber Laser high cost efficient fiber laser